What is MHPII (Micro-Hole Pack II)?

This is the general term for our rice bags made of laminate or polyethylene (PE) materials with ultra-fine perforations on one surface, and our rice bags made of PE material where one surface has a degassing function. (Patent pending)

Features of MHPII

- ・

- Ultra-micro holes block entry by foreign matter, such as insects or dust.

- ・

- The task of filling rice bags work can be carried out using existing equipment, with no new degassing equipment etc. needed.

Water penetration comparison testing for MHPII

[Drip testing]

Method

We prepared several 5 kg rice bags (of polished white rice), including MHPII-specified rice bags and conventional rice bags.

We conducted a comparison of mold generated under controlled conditions. A certain amount of water was dripped onto both bags from above, and then the bags were left for two weeks at an indoor temperature of 30°C and 90% humidity, after which the amount of mold was measured.

Results

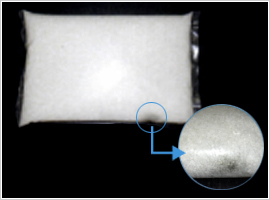

MHPII-specified rice bags

Conventional (perforated) rice bags

A clear difference was confirmed. No mold was observed in the MHPII-specified rice bag, while it was confirmed that mold had occurred in the conventional (perforated) rice bags, as shown in the photograph.

[Airflow testing]

Method

We prepared several 5 kg rice bags (of polished white rice), including MHPII-specified rice bags and conventional rice bags.

After the bags were left for two weeks at an indoor temperature of 30°C and 90% humidity, the amount of moisture within each bag was measured.

Results

| Moisture content after 1 week (%) | Moisture content after 2 weeks (%) | |

| MHPII laminate bag | 13.45 | 15.80 |

| MHPII PE bag | 13.45 | 15.21 |

| Conventional product (perforated bag) | 13.45 | 19.90 |

There was a noticeable difference between the MMHPII-specified bags and the conventional product (perforated bags).

The above measurements were conducted at the Material Application Support Center within the Industrial Research Institute of Niigata Prefecture.